Quality Control in Nylon Spandex Fabric Production

Introduction

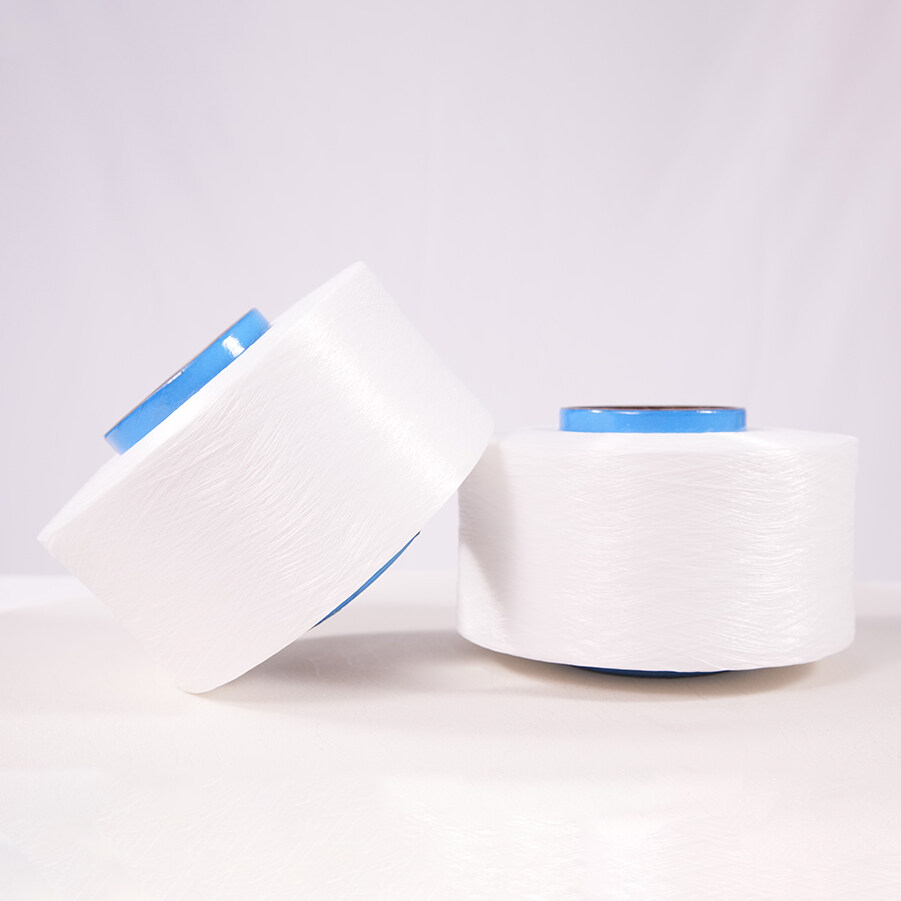

Quality control is the cornerstone of any manufacturing process, and the production and distribution of nylon spandex fabric are no exception. In the textile industry, where precision and consistency are paramount, implementing robust quality control measures is crucial to ensuring that the final product meets the desired standards of strength, elasticity, colorfastness, and other essential attributes. This article delves into the significance of quality control and testing procedures in the production and distribution of nylon spandex fabric, highlighting the various testing procedures employed to uphold quality standards.

Quality Control Measures

At the heart of quality control lies a comprehensive set of procedures designed to monitor and evaluate every stage of the production process. From raw material inspection to final product testing, quality control ensures that each step meets predetermined quality criteria. In the realm of nylon spandex fabric production, quality control measures encompass a range of activities, including raw material testing, in-process inspections, and final product testing. These measures not only help identify defects and inconsistencies but also enable timely corrective actions to maintain product integrity.

Testing Procedures

Testing procedures play a pivotal role in quality control, providing objective assessments of key attributes such as strength, elasticity, and colorfastness. In the context of nylon spandex fabric, several testing methods are employed to rigorously assess these attributes. Strength testing involves evaluating the fabric's tensile strength and tear strength to determine its resistance to external forces and tearing. Elasticity testing measures the fabric's ability to stretch and recover, ensuring optimal comfort and durability.

Colorfastness testing is another critical aspect of quality control, especially in textiles exposed to frequent washing and wear. By subjecting the fabric to various environmental conditions, such as washing and rubbing, colorfastness tests assess its resistance to fading and color transfer. Additionally, other relevant attributes, such as abrasion resistance and pilling resistance, are also evaluated to gauge the fabric's performance under different usage scenarios.

Importance of Each Attribute

Each attribute tested holds significant importance in determining the overall quality and performance of nylon spandex fabric. Strength is essential for ensuring durability and structural integrity, especially in applications where the fabric is subjected to repeated stretching and stress. Elasticity, on the other hand, contributes to the fabric's comfort and fit, allowing it to adapt to body movements without losing shape.

Colorfastness is critical for maintaining the fabric's aesthetic appeal over time and preserving its vibrant colors and patterns through multiple wash cycles. Other attributes, such as abrasion resistance and pilling resistance, are equally important, as they affect the fabric's longevity and appearance.

Compliance with Standards and Regulations

Adherence to industry standards and regulatory requirements is imperative in the textile industry to ensure product safety and quality consistency. Various organizations, such as the American Association of Textile Chemists and Colorists (AATCC) and the International Organization for Standardization (ISO), have established standards for testing methods and performance criteria specific to nylon spandex fabric.

Technologies and Tools Used in Testing

Advancements in technology have revolutionized the field of textile testing, enabling more accurate and efficient evaluation of fabric properties. Advanced testing equipment, such as universal testing machines and spectrophotometers, allows for precise measurements of strength and colorfastness. Additionally, software tools for data analysis facilitate the interpretation of test results, enabling manufacturers to make informed decisions and improvements in their production processes.

Challenges and Solutions

Despite the benefits of quality control and testing procedures, manufacturers may encounter various challenges in implementing these measures effectively. Common challenges include resource constraints, variability in raw materials, and evolving customer expectations. To address these challenges, manufacturers must invest in training programs, establish robust supplier relationships, and continuously monitor and adapt their quality control processes to meet changing demands.

Continuous Improvement in Quality Control

Continuous improvement is central to maintaining high standards of quality in nylon and spandex fabric production. By establishing a feedback loop for process improvement and incorporating customer feedback, manufacturers can identify areas for enhancement and implement corrective actions proactively. Additionally, fostering a culture of quality consciousness among employees and stakeholders is essential for sustaining long-term success in quality control.

Conclusion

In conclusion, quality control and testing procedures are indispensable elements of nylon spandex fabric production, ensuring that the final product meets stringent quality standards. By employing rigorous testing methods and adhering to industry regulations, manufacturers can uphold product integrity, enhance customer satisfaction, and drive business growth. As technology continues to evolve and consumer preferences evolve, maintaining a steadfast commitment to quality excellence will remain paramount in the competitive textile industry.