Para-Aramid Fiber Makers: Strength & Innovation

Introduction:

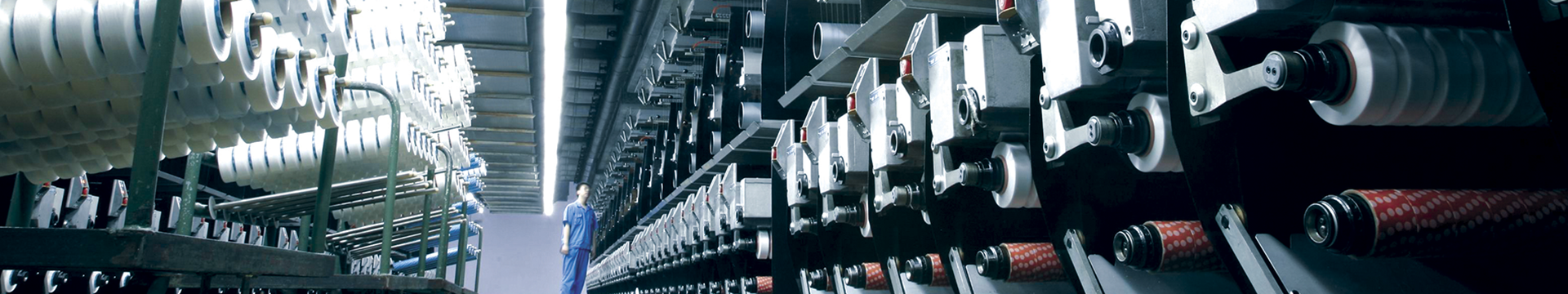

In the intricate tapestry of modern industry, para-aramid fibers stand out as a marvel of engineering. These remarkable fibers, renowned for their exceptional strength, heat resistance, and lightweight properties, have become indispensable in a wide array of applications. Behind the scenes, a select group of manufacturers play a pivotal role in weaving these fibers into the fabric of our everyday lives. Let's delve into the world of para-aramid fiber manufacturers, exploring their innovations, challenges, and the impact of their work on diverse industries.

1. The Genesis of Para-Aramid Fibers:

Para-aramid fibers trace their origins back to pioneering research conducted in the mid-20th century. Initially developed by Stephanie Kwolek at DuPont, these synthetic fibers gained prominence for their extraordinary strength-to-weight ratio and resistance to high temperatures. Today, para-aramid fibers are synonymous with brands like Kevlar® and Twaron®, setting the gold standard for performance in fields ranging from aerospace to ballistic protection.

2. Leading Manufacturers:

a. DuPont: As one of the earliest pioneers in para-aramid fiber production, DuPont remains a titan in the industry. With decades of expertise and a global footprint, DuPont continues to innovate, pushing the boundaries of performance and versatility in para-aramid applications.

b. Teijin Aramid: Renowned for their brand Twaron®, Teijin Aramid has established itself as a leading supplier of high-performance para-aramid fibers. Their commitment to sustainability and technological advancement has propelled them to the forefront of the market.

c. Kolon Industries: Based in South Korea, Kolon Industries has emerged as a key player in para-aramid fiber manufacturing. Leveraging advanced production techniques, Kolon delivers cutting-edge solutions for diverse industries, including automotive and construction.

3. Innovations Driving Progress:

Para-aramid fiber manufacturers continuously push the boundaries of innovation, seeking to enhance performance and unlock new applications. Recent advancements include:

Nanostructuring: By incorporating nanotechnology, manufacturers are able to further enhance the mechanical properties of para-aramid fibers, paving the way for lighter and stronger materials.

Functionalization: Surface modifications enable para-aramid fibers to exhibit enhanced chemical resistance, opening doors to applications in harsh environments such as chemical processing and oil exploration.

Hybrid Composites: Combining para-aramid fibers with other materials such as carbon fibers or thermoplastics results in hybrid composites with tailored properties, catering to specific performance requirements in industries like automotive and sporting goods.

4. Challenges and Future Outlook:

Despite their remarkable attributes, para-aramid fibers face challenges such as cost constraints and competition from alternative materials. Moreover, ensuring sustainable production practices remains a priority for manufacturers amid growing environmental concerns.

Looking ahead, the future of para-aramid fiber manufacturing holds promise. Advancements in recycling technologies, coupled with increasing demand for lightweight and high-strength materials, are poised to drive growth in the industry. Moreover, emerging applications in fields like 3D printing and wearable technology present exciting opportunities for innovation.

Conclusion:

In the dynamic landscape of materials science, para-aramid fibers shine as a testament to human ingenuity and perseverance. Behind these extraordinary fibers lie dedicated manufacturers, tirelessly innovating to meet the evolving needs of diverse industries. As we unravel the intricacies of para-aramid fiber manufacturing, we gain insight into the remarkable journey from research laboratories to everyday applications, where strength, durability, and innovation converge to shape the world around us.