Exploring Aramid Paper Insulation Manufacturing

In the realm of industrial innovation, certain materials often go unnoticed despite playing pivotal roles in various applications. Aramid paper insulation is one such unsung hero, quietly revolutionizing industries with its remarkable properties and versatile applications. Today, let's embark on a journey to unravel the mysteries behind this fascinating material, exploring its manufacturing process and the myriad wonders it brings to the table.

Origins and Composition

Aramid paper insulation is crafted from aramid fibers, renowned for their exceptional strength, heat resistance, and dielectric properties. These fibers, derived from aromatic polyamide polymers, are meticulously processed to form a thin yet robust paper-like material. The key to its unparalleled performance lies in the unique arrangement of molecular bonds within the fibers, which grants aramid paper remarkable thermal stability and mechanical strength.

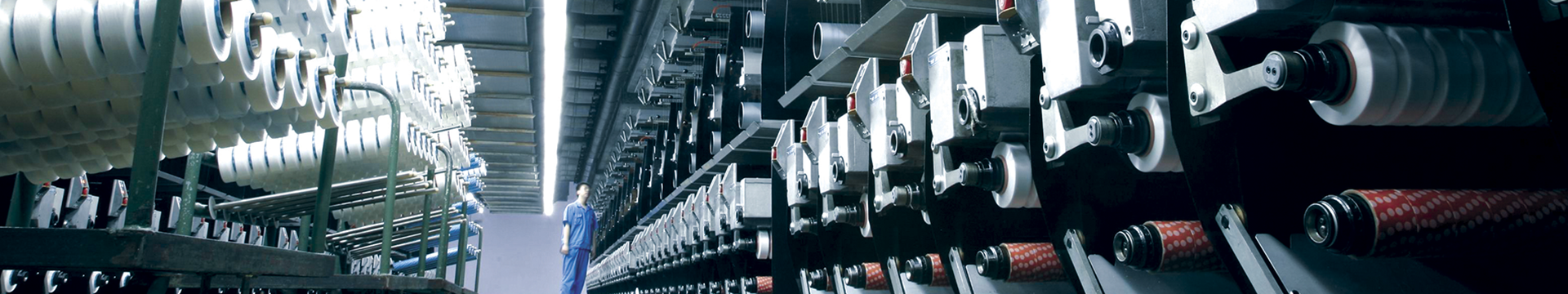

Manufacturing Process

The manufacturing process of aramid paper insulation is a testament to precision engineering and scientific ingenuity. It begins with the dissolution of aramid polymer pellets in a solvent, forming a viscous solution. This solution is then cast onto a moving belt or drum, where it undergoes a series of controlled drying and curing stages. The result is a thin sheet of aramid paper with uniform thickness and impeccable integrity.

Next comes the crucial step of calendering, where the aramid paper undergoes high-pressure compression between heated rollers. This process not only enhances the material's density and smoothness but also aligns the aramid fibers in a uniform orientation, optimizing its mechanical and electrical properties.

Applications Across Industries

Aramid paper insulation's exceptional properties render it indispensable across a myriad of industries. In the electrical sector, it serves as insulation for high-voltage cables, transformers, and motors, safeguarding critical components against electrical breakdown and thermal degradation. Its remarkable dielectric strength ensures reliable performance even in the most demanding environments.

Moreover, aramid paper finds extensive use in aerospace and automotive applications, where lightweight materials with superior mechanical strength are paramount. From reinforcing composite materials to providing thermal insulation in engine compartments, its versatility knows no bounds.

Future Prospects and Innovations

As technology advances and demands for high-performance materials escalate, the future of aramid paper insulation looks brighter than ever. Researchers are exploring novel manufacturing techniques, such as electrospinning and nanocomposite formulations, to further enhance its properties and expand its applicability. Additionally, efforts are underway to improve the sustainability of aramid production processes, ensuring minimal environmental impact without compromising performance.

In conclusion, aramid paper insulation stands as a testament to human ingenuity and the boundless potential of advanced materials. From its humble beginnings in research laboratories to its ubiquitous presence in critical industries, its journey is a testament to the power of innovation. As we continue to push the boundaries of scientific discovery, one thing remains certain: the remarkable legacy of aramid paper insulation will endure for generations to come.